QUALITY TRIUMPHS COST ── LESSONS FROM A LEADING VIETNAMESE INDUSTRIAL PLAYER CHYI YANG'S CUSTOMER-CENTRIC APPROACH

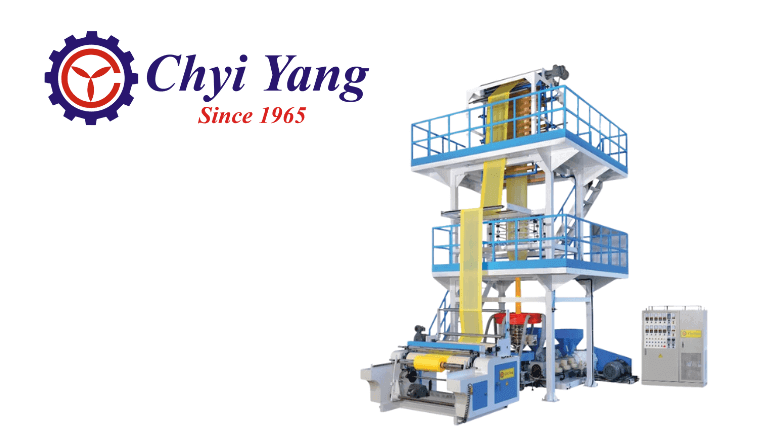

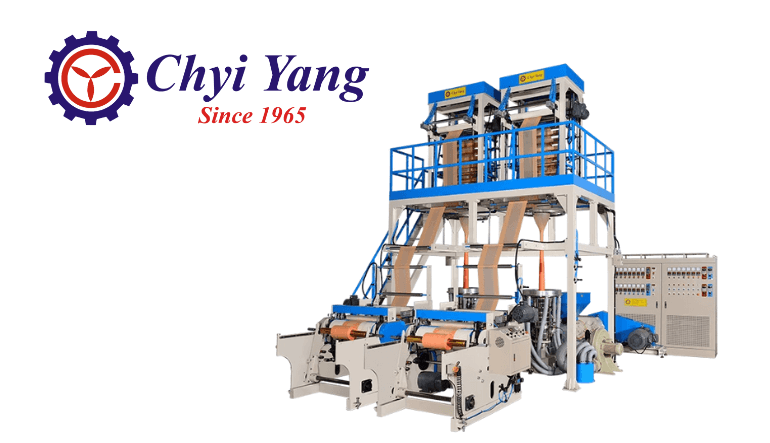

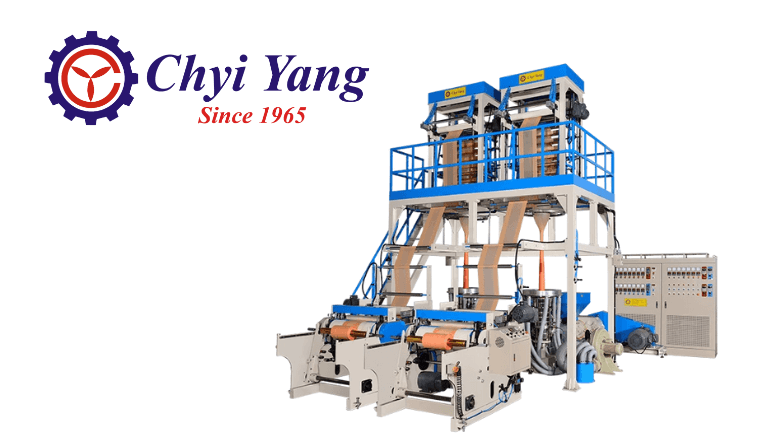

International Plastics News for Asia | Chi-Chuan Cheng The crucial consideration for manufacturers is whether to cut costs or enhance value. There is a well-established plastic film producer located in Hanoi, Vietnam, which a few years ago purchased blown film machines from the renowned quality-driven company, Chyi Yang. However, due to price considerations, the factory later shifted to purchasing low-cost multilayer blown film machines manufactured in China, temporarily expanding its production capacity. Despite momentarily stepping back from the price competition, Chyi Yang remains steadfast in its commitment to quality-driven development, continuously innovating and advancing with the introduction of various styles of 5-layer / 7-layer co-extrusion blown film machines.

Path to a Greener Tomorrow── Chyi Yang's CFV Solutions of Precision and Sustainability

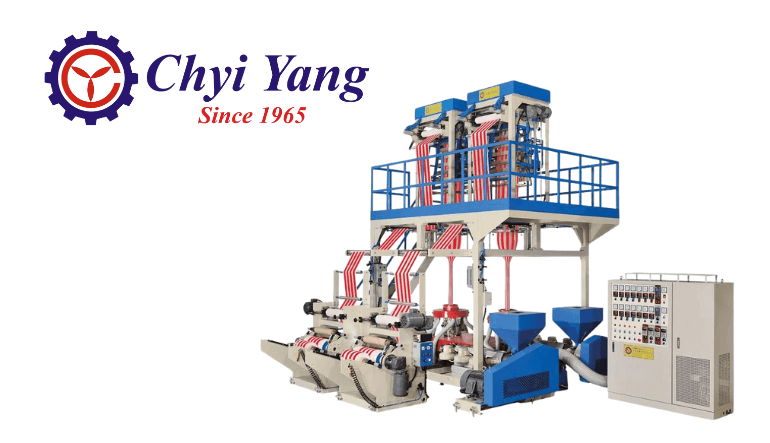

Global environmental awareness has prompted the manufacturing industry to transition towards green production. The need for "carbon reduction" in the CFV stages has led the global blown film manufacturing industry to pursue sustainable development solutions. Chyi Yang's 5-layer / 7-layer co-extrusion blown film machines have become a key player in today's green supply chain due to their three key advantages: "Big Data Analysis," "Precision Formulation and Calculation Functions," and "Recycled Waste Technology Innovations" in their multi-layer blown film machines. The international blown film manufacturing market also recognizes the indispensability of Chyi Yang in the trend of carbon reduction.

CHYI YANG: Transforming Waste into Gold, ABA Co-extrusion Machine Revolutionized Bag Manufacturing

The unique die head design of the ABA co-extrusion machines offers producers cost management flexibility by incorporating an middle layer of recycled material or calcium carbonate compound, effectively reducing raw material expenses. This not only maintains competitiveness in raw material prices but also aligns with environmental trends.

ETERLONG: Your All-In-One Solution for Blown Film Machines

ETERLONG – A merger with the leading Blown Film Die manufacturer former brand HSIN LONG. Continuation of HL spirit and experiences, in addition, ETERLONG have advanced production facilities and acquire IoT (Internet of Things) intelligent equipment to expand production capacity. We are dedicated to create All-in-One to deliver great service to make customers simple choices, they can purchase not only individual components but also complete Blown Film Machines, all from ETERLONG.

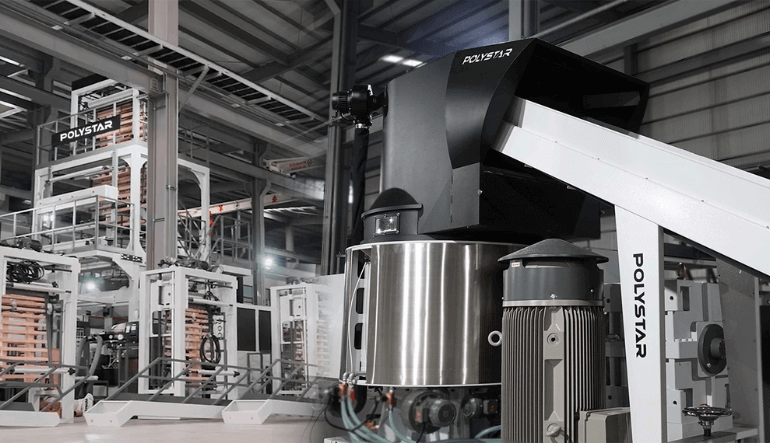

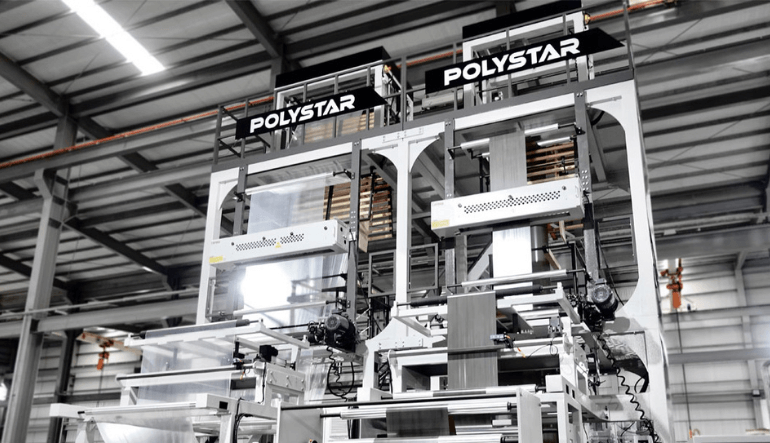

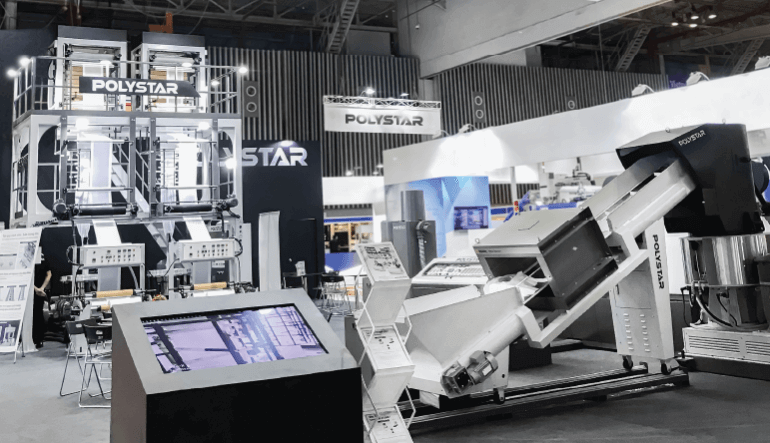

POLYSTAR Co-extrusion & Recycling: Making Plastic Film Sustainable

With the increasing concern over plastic waste and pollution, plastic bag manufacturers are looking for more sustainable production methods to diminish the negative effects of their plastic products. Co-extrusion and recycling are two techniques that are gaining popularity in the plastic film industry. In this blog, we will explore how co-extrusion and recycling can create a circular economy for plastic bag production and minimize waste.

Flexible POLYSTAR Blown Film Extruders for Sustainable Packaging

Eco-friendly packaging is a necessity more than a trend, for both environmental and economic sustainability today. As one of the main carriers of packaging film production, blown film extrusion technology must keep evolving to meet the market requirements. Let's take a closer look into how POLYSTAR develops its blown film extrusion machine technology to better contribute to eco-friendly packaging.

CACO3 & RECYCLING MATERIAL REVOLUTION IN HDPE BAGS

Nowadays, for HDPE shopping bags, T-shirt bags & food packaging bags, it’s very popular to blend recycled material & calcium carbonate (CACO3). Especially CACO3, it can cut down your resin cost, increase capacity & make your film products heavier. Although CACO3 provides so many advantages, it changes the feature of HDPE film. HDPE film will be reduced in tensile strength after blending CACO3, so that HDPE film won’t pack heavy subjects. Besides, CACO3 will make HDPE film feels dusty.

ADVANTAGES OF ABA CO-EXTRUSION BLOWN FILM MACHINE

A co-extrusion process uses more than one polymer to form the plastic bubble and therefore more layers to the film. The most prevalent blown film process today is the ABA co-extrusion process. One of CHYI YANG's most popular machines is also the ABA co-extrusion blown film machine. The term ABA indicates the three-layer structure of the film, two outer layers, and one inner layer, hence ABA. The materials of the A layer and B layer are different. The outer layer typically uses new materials, whereas the inner layer uses recycled materials. Using more than one material leads to several advantages and installation adjustments on the ABA blown film machine. As a leading plastic film machinery manufacturer in Taiwan, today CHYI YANG will talk about the advantages of this kind of blown film machine and how it can help your business.

Revolutionizing the Market: Chyi Yang's Smart 5/7-layer Blown Film Machines Lead the ESG Sustainability Trend

Chyi Yang's Smart 5/7-layer Blown Film Machines revolutionize plastic film production, reducing costs and material waste while complying with regulations. Their Auto-recycling blown film machines use precision formula calculations and advanced recycling mechanisms to improve production yield and achieve "ZERO WASTE" while reducing energy consumption to improve competitiveness.

SUPER HIGH SPEED HDPE CAPACITY BLOWN FILM MACHINE IN LESS SPACE

Chyi Yang showed one set “Two Stripes & Two dies Co-Extrusion Blown Film Machine” in Andina-Pack 2015 Colombia exhibition. This machine is equipped with two dies & two extruders to produce two stripes T-shirt bags for market using. The two 45mm extruders provide two dies to have 2-line film rolls at one time. Forced feeding extruders offer you bigger capacity, the max. capacity is 140kgs/hr. for 550mm film width at 20micron film thickness. You can get max. 70kgs/hr. from each winder, and max. 140kgs/hr. from two winders.

GUIDE TO BLOWN FILM EXTRUSION MACHINES

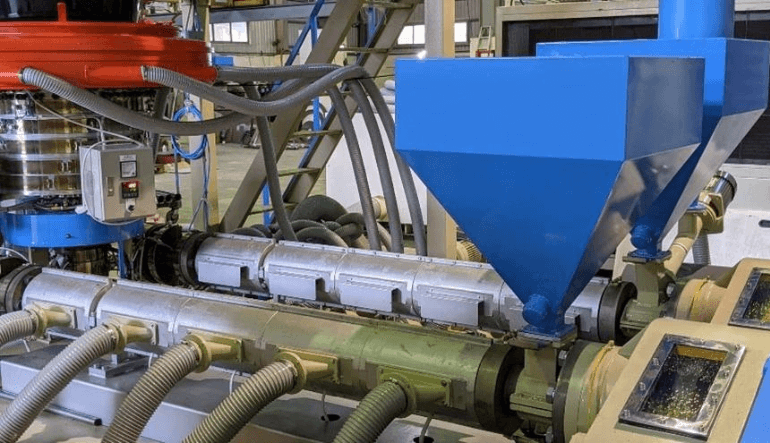

The process to produce the film is similar to blowing bubbles. The blown film machine virtually replicates the blowing process on its tower-like production line except it uses polymers (plastic materials) to replace soap water and nip the continuously blown bubble into an extremely thin film. The tower structure ranges several stages high. After the film is formed, it is wound into rolls and later distributed for final applications. As one of the leading blown film extrusion machine manufacturers with over 50-year-experience in Taiwan, now CHYI YANG is going to break down the process into details and discuss how blown film extrusion works.

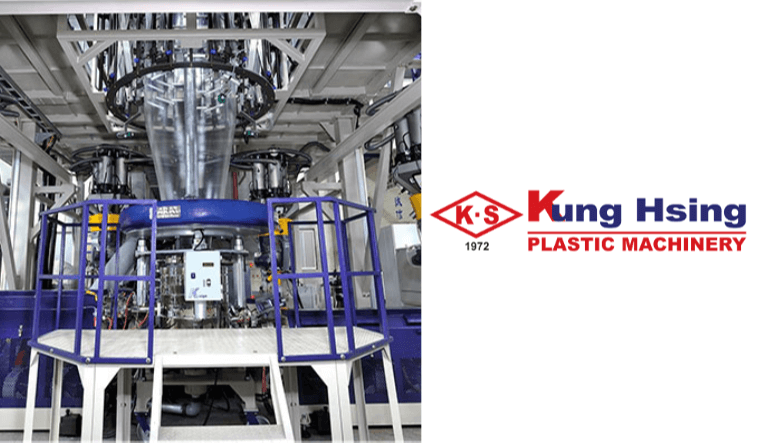

Kung Hsing's Sustainable Solutions: Revolutionizing the Plastic Industry for a Greener Future

Sustainability is about our next generations, and it is what we give them when we leave the world. The resources on our planet are limited, and it would be exhausted one day. Plastic Industry is commonly associated with a destructive factor to the environment. However, people should be aware that not all plastic is disposable, and most of them could be reuse and recyclable. More and more countries had different policy on the plastic, in order to reduce the plastic consumption volume.

Eterlong in PLAST EURASIA ISTANBUL 2023 and Plastivision India 2023

Eterlong Co., Ltd. is pleased to participate in the annual events PLAST EURASIA ISTANBUL 2023 and Plastivision India 2023 with great enthusiasm. As our growing audience discovers the potential of impressive products demonstrations, fruitful buyer-seller meetings, and engaging discussions with industry professionals, People's expectations for the products and services Eterlong can offer are higher than ever.

Let’s Work Together Towards an Eco-friendly Future with JANDI’S!

JANDI'S offers various high-quality Equipment for plastic film & bags, such as Blown Film Machine, Cutting & Sealing Machine, Printing Machine & Plastic Film Recycling Machines. Since 2013 JANDI'S has been working on the machines of biodegradable film and bags. We would like to promote the new generation machines that care about the environment.

Find the Latest POLYSTAR Solutions at These Upcoming Plastic Exhibitions of the Year

Having the advantage of attending over 20 global exhibitions annually, in the last quarter of 2023, we sustain the excitement of meeting you at one of the upcoming exhibitions in your region. As a leading plastic recycling machine and blown film machine manufacturer from Taiwan, we can’t wait to share POLYSTAR solutions with you, that would make your plastic business simpler.

5 Advantages of POLYSTAR for Your Plastic Recycling and Blown Film Businesses

As a leading manufacturer in the plastic industry, more than 4950 POLYSTAR plastic recycling machines and blown film extruders are operating in 110 countries today. This is a result of our satisfied customers, who have experienced the advantages of using POLYSTAR machines for their businesses. Here we have listed 5 of those advantages that are most pointed out based on our customers' feedback.

KUNG HSING: Innovative Multilayer Blown Film Designs — Key Considerations for Optimal Performance

In recent years, there have been remarkable advancements in blown film technology, leading to the creation of inventive multilayer blown film designs. These designs surpass traditional monolayer films in terms of barrier properties, strength, and versatility. Nevertheless, attaining peak performance necessitates thoughtful attention to various crucial factors throughout the design process. This article will delve into the essential considerations for achieving optimal performance in innovative multilayer blown film designs.

JANDI’S - The Differences in the Nature of PE & Biodegradable Material (PLA/PBAT Based)

According to the material supplier, bio-degradable material cannot be recycled easily. But, if not trying to recycle, the disposal of the waste & die-cut from bio-degradable material will become big additional expenses. Even if you may recycle the bio-degradable material, the time, space and workman ship required for the collection of the waste, will already create additional costs. Because of the above reasons, JANDI’S JIT is the best solution for the production of PLA/PBAT Bio-Degradable T-shirt bags.

A Guide Selection for Plastic Printing Machine

Printing technology is crucial in the plastic and rubber industry for creating vibrant packaging. This article aims to introduce the most commonly used printing machines to global buyers, including rotogravure printing machines and flexographic printing machines. By providing descriptions, advantages, and features of these printing machines, you will understand how to select the printing equipment that suits your specific needs.

Blown Film Machine vs. Blow Molding Machine: Difference and Comparison

Blown film machines and blow molding machines are easily confused by many people, but they are two totally different machines and function differently as well. In this article, we will be discussing each machine and how they operate.

BARM for Success : How JANDI'S Implements Mr. Jerry's Concept to Enhance Machinery Supply

First of all, we would like to share some good news with you. While JANDI’S celebrate our 32nd anniversary on January 23, 2023, the General Manager of our company, Mr. Jerry M. J. Huang, graduated from the Department of Business Administration, National Chung Cheng University, and got his Ph.D. degree.

How to Start Plastic Recycling Business? A Complete Guide to Choosing the Right Recycling Machine

Plastic recycling is a growing industry. There are numerous factors to consider if you want to start a recycling business. You must decide what types of plastics you will recycle, determine the location of your business, research local and state requirements, research your customers, set up accounts with plastic buyers, and, most importantly, invest in a reliable plastic recycling machine.

Sustainability Benefits for Plastic Film Producers

Why do producers want to recycle plastics? Although plastic is a very popular material, on a global level, less than 10% of it is recycled. With plastic waste being in such a high supply, producers could benefit from incorporating recycling into their existing business model. A recent study by business and daily found that 72% of the respondents are actively buying more environmentally friendly products than they did 5 years ago.

HAN KING: Review K-2022 - Post Consumer Recycling for Environmental Resource Circulation

At K-2022, Han King displayed its five-layer heavy duty sack blown film production line comprising in-line printing machine and embossing device, via real time live streaming from their manufacturing plant. The resin formulation was supported by Borouge, with 30% post-consumer recycled resins.